Substrates

Before you can work with thin films you have to get to know the substrates you are going to use. Substrates are part of the model and their optical constants (=complex refractive index n + i k) determine how light waves are reflected and absorbed.

In the case of transparent substrates (glass panes or plastic plates) it is sufficient to record reflectance and transmittance spectra and to measure the mechanical thickness of the plate. You can then adjust a model for the optical constants.

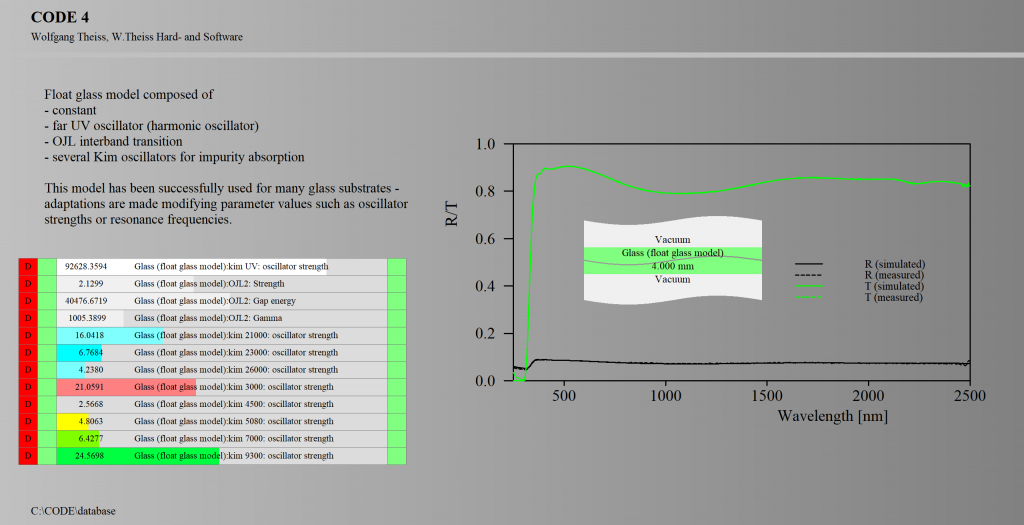

Here is a float glass example:

Sometimes substrates have some thin films already, like glass panes that come with a conductive coating, or a silicon wafer with an SiO2 layer. In this case the optical model should include these layers – it may be necessary to contact the producer to get information about the type of substrate coating and approximate thickness values.

Single layers

Deposit single layers of your material candidates on known substrates. Then record optical data like reflectance, transmittance or ellipsometric spectra. Analyze the spectra adjusting a suitable optical model and get the complex refractive index of the material as well as the layer thickness (please read this about selecting the right model for optical constants). You now know what materials and which deposition rates you can use designing new thin film products.

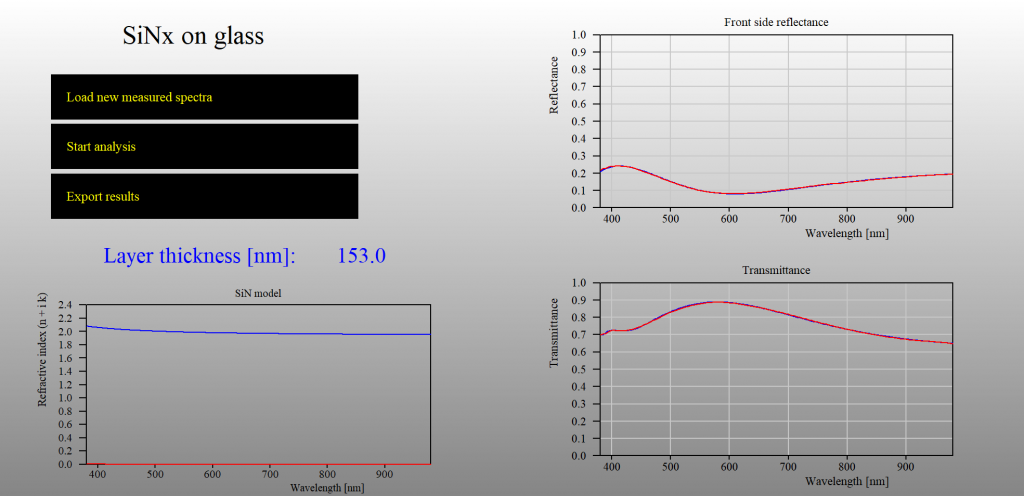

The first example is a SiNx layer on glass. The blank glass had been analyzed before the deposition. The model adjusts a so-called OJL model for interband transitions. This model turned out to be perfect for numerous for oxides and nitrides. For this kind of problems you can generate very simple user interfaces in the main view of CODE. This allows easy but safe thin film analysis done by unexperienced operators.

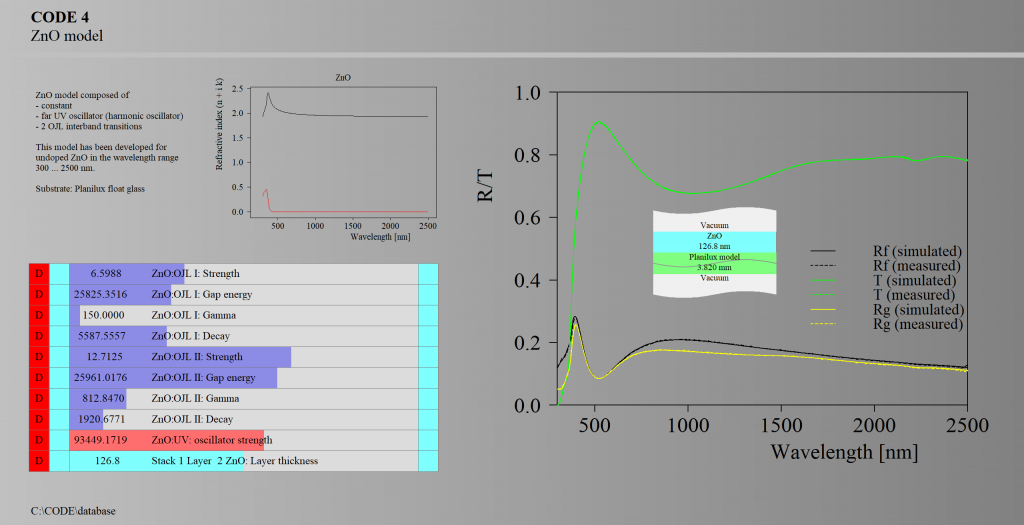

In a few cases we found that you have to do a little more than just using a single OJL model. Fortunately, you can add more complexity to the optical constant model if you have to. Here is a single layer example of ZnO which requires 2 OJL models for correct UV properties:

Conductive layers require the addition of a Drude model (or a so-called ‘Extended Drude model’) which takes care of the response of the free charge carriers.

Master model for stoichiometry variations

The optical properties of suboxides (or subnitrides) depend critically on the concentration of oxygen (or nitrogen) atoms incorporated into the layer. If you vary the composition on purpose you can produce materials with different optical constants. For such a situation CODE provides a very elegant ‘master model’: Analyzing several single layer examples CODE learns how the optical constants change with composition. It then generates a model that scans continuously through all known cases and does interpolation in between. With a single oxygen parameter you are then able to cover the stoichiometry influence on the optical constants. This can be extremely helpful if you need specific optical constants for a design.

Beyond single layers

You may find that a simple single layer model does not work well for some samples. In that case you should consider one or more of the following cases:

- Surface roughness

- Depth gradient of the layer composition

- Losses of light due to scattering at the surface or in the volume of the layer (haze)

For all these cases you can use mechanisms built into the CODE software.