BREIN – BRight Eye Inspection Network

Software for optical production control of large area coating lines

BREIN program modifications and bugfixes

Download current program versions

The production of large area coatings usually involves many sputtering cathodes in the coating line each one contributing a certain amount of uncertainty about what is produced at the moment.

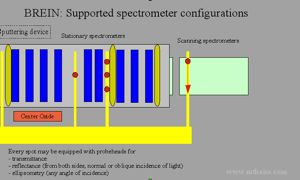

An optical production control is required, providing online information about the coating produced at present. In most cases transmittance, reflectance or ellipsometry spectra are recorded, either inline between groups of cathodes or directly behind the coating line when the final products have left the vacuum:

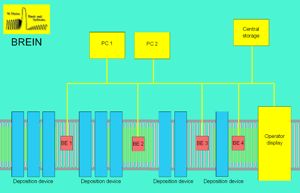

Based on the CODE software (a program for analysis and design of thin film products), W.Theiss Hard- and Software has developed the software package BREIN which is dedicated to the optical control of the production of multilayer coatings in large coating lines. BREIN stands for BRight Eye INspection network: It manages several stations called ‘Bright Eyes’ (BE) which analyze optical spectra taken at a certain position in or after the coating line:

Before doing the analysis for a product, each BE picks up the results obtained by the BE prior in the line. This way only the newly deposited layers after the last BE have to be analyzed – the computational effort for each BE is usually quite low and can be done even on slow embedded computers. Alternatively several BE analysis steps can be done on one and the same computer. The main BREIN application collects the BE results and displays the current status of the production. The operators can use this information for making decisions about changes of the production conditions. The graph below shows the scheme of a typical BREIN setup. The spectra recorded at the Bright Eye stations BE1 … BE4 are stored on a central server and analyzed on two computers (PC 1, PC 2).

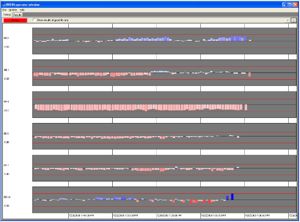

The results of the analysis are stored in database records on the central storage device:

The database content can be filtered and viewed in various ways providing information about the history of the production. On the operator level important coating parameters are displayed in a graphical way indicating too high values in blue and too low values in red. Warning levels of parameter values are indicated by red lines. The operators can easily check the time evolution of the coating parameters as shown in the following screen shot:

Bright eye stations which scan across the panes can compute and export statistical parameters for the obtained parameter profiles. The average, standard deviation and range of the parameters are determined. You can define specifications for these values and classify panes as ‘Good’ or ‘Bad’, depending on the performance of the pane with respect to the profile statistics.

BREIN can be coupled to Zeiss OptoPlex NG.Q systems which are widely used in large area coaters.

BREIN can be connected to an external SQL database to export the production control results.

Take a look at our videos about optical production control for large area coaters.