Object generation 3.98

We have been using CODE for a long time already to show interactive presentations about thin film optics. The related program features are now official parts of the software.

A CODE presentation is basically a sequence of configurations that provide the individual pages of the presentation. There are some mechanisms to navigate through the presentation. If you maximize CODE and put it into presentation mode (key ‘p’ on your keyboard) you can show full screen presentations that look like Powerpoint. Inside, however, you are using fully functional CODE configurations with all slider and animation features.

There are view elements for easy navigation. You can have a table of contents providing direct access of every page (on the left side in the image below) and a control to jump to the next, previous or first page (upper right corner):

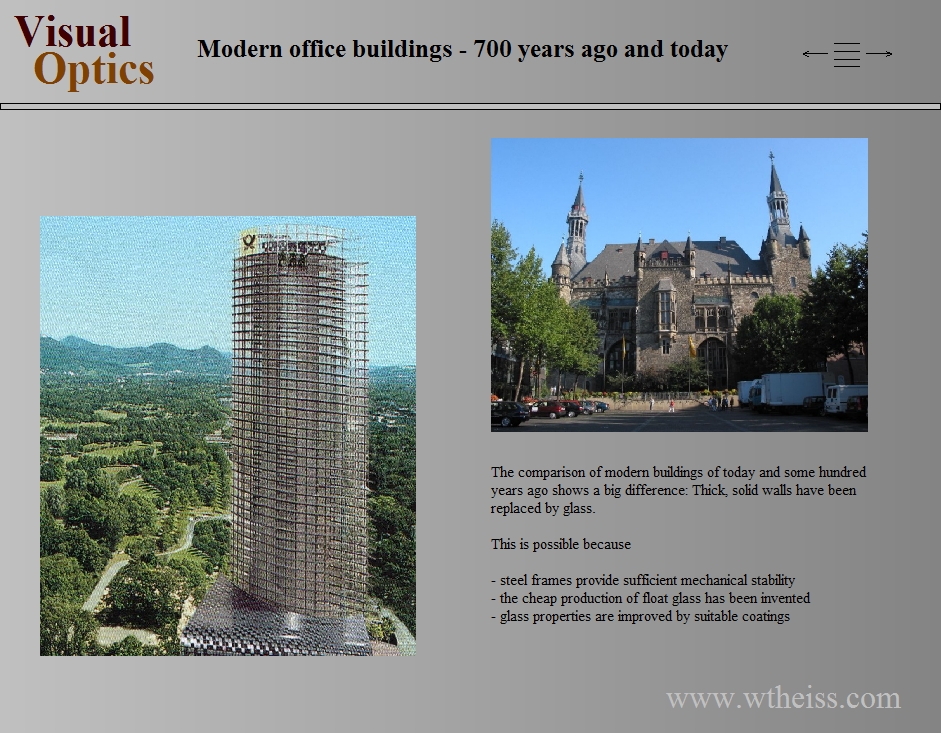

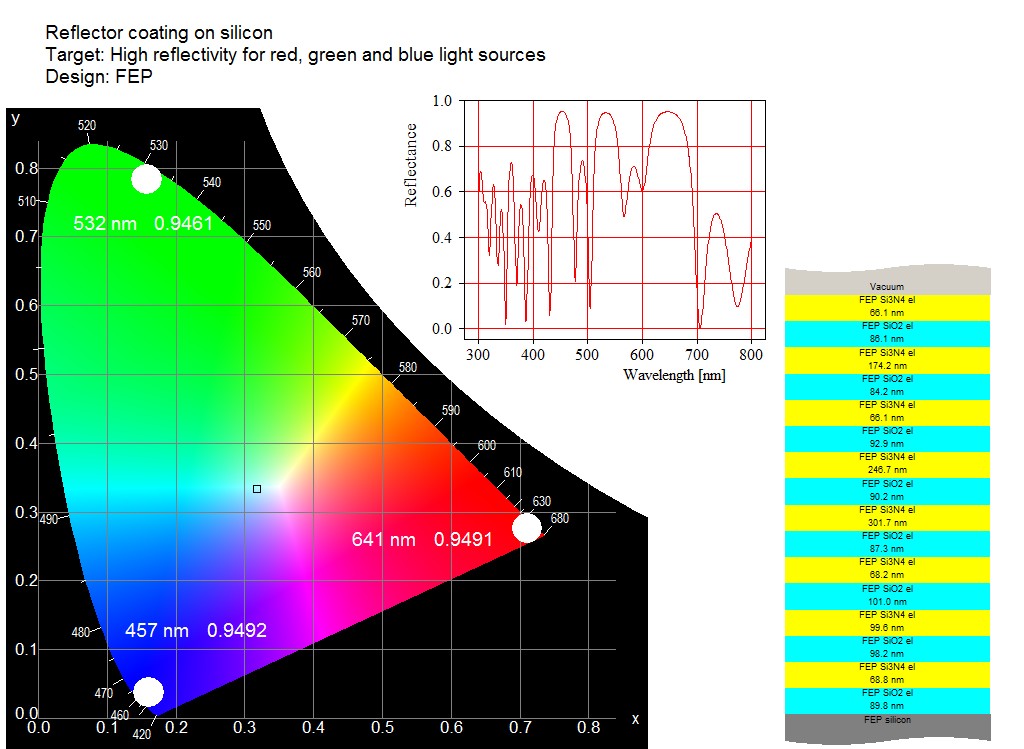

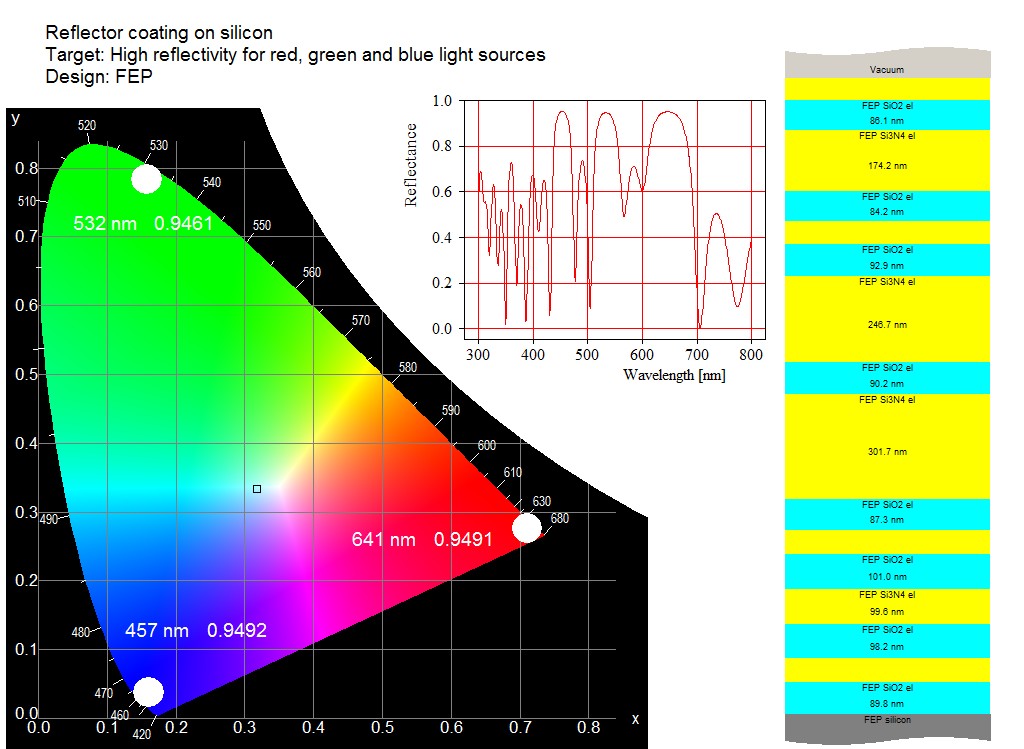

Your pages (=configurations files) can be either static

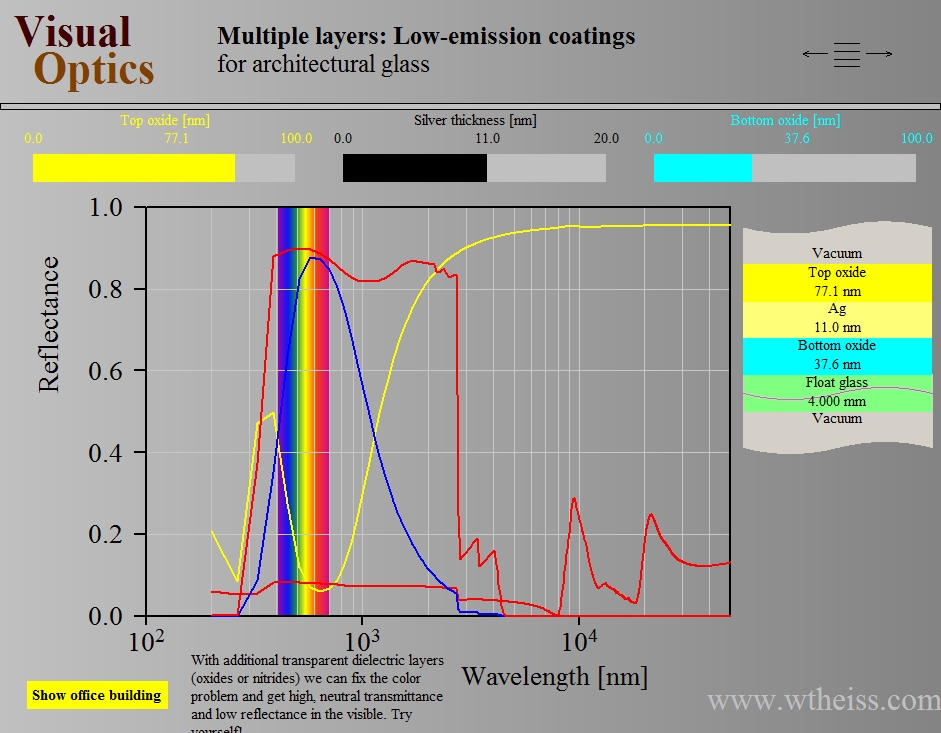

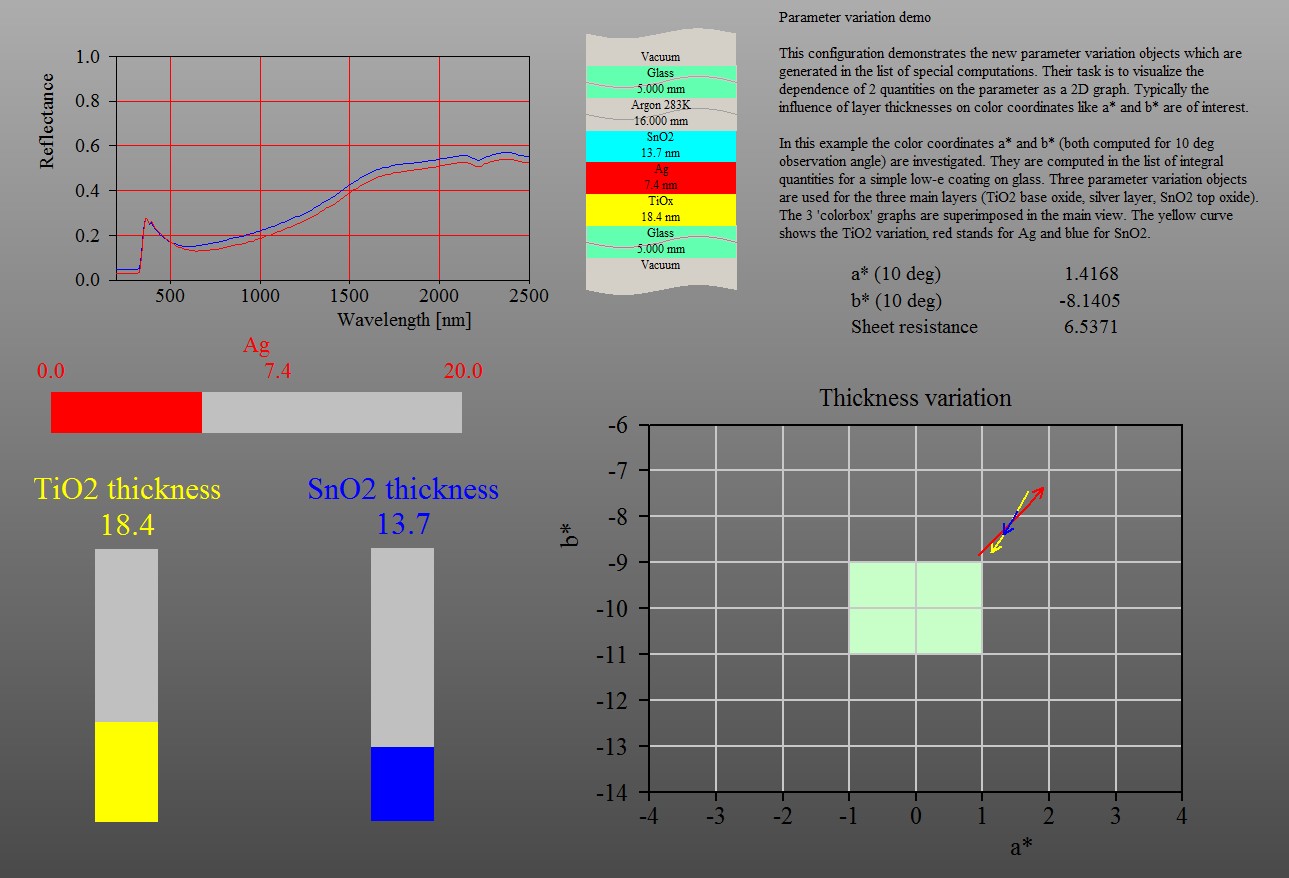

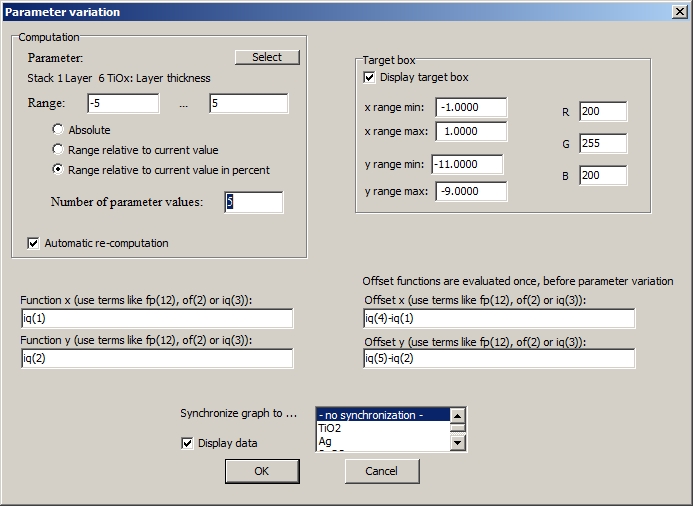

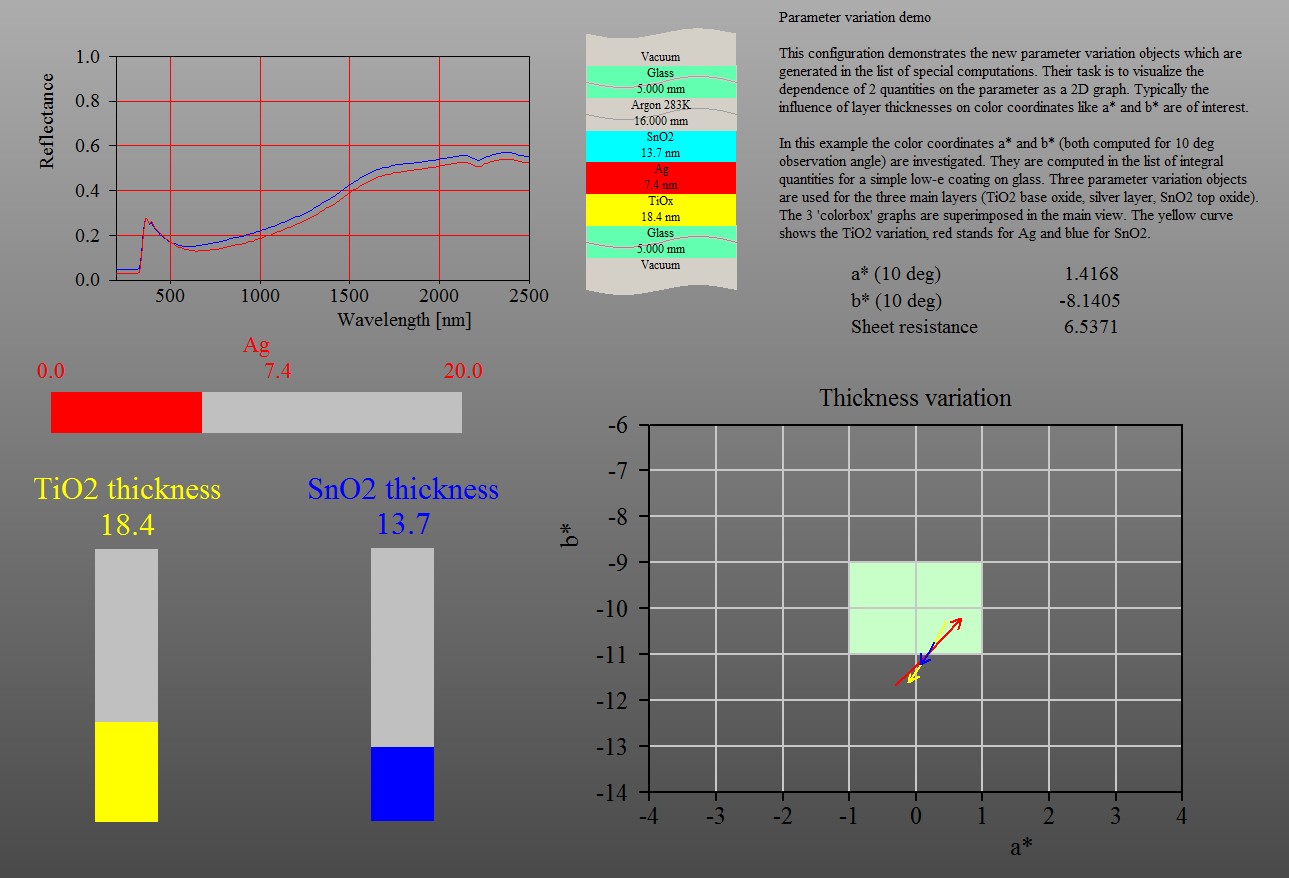

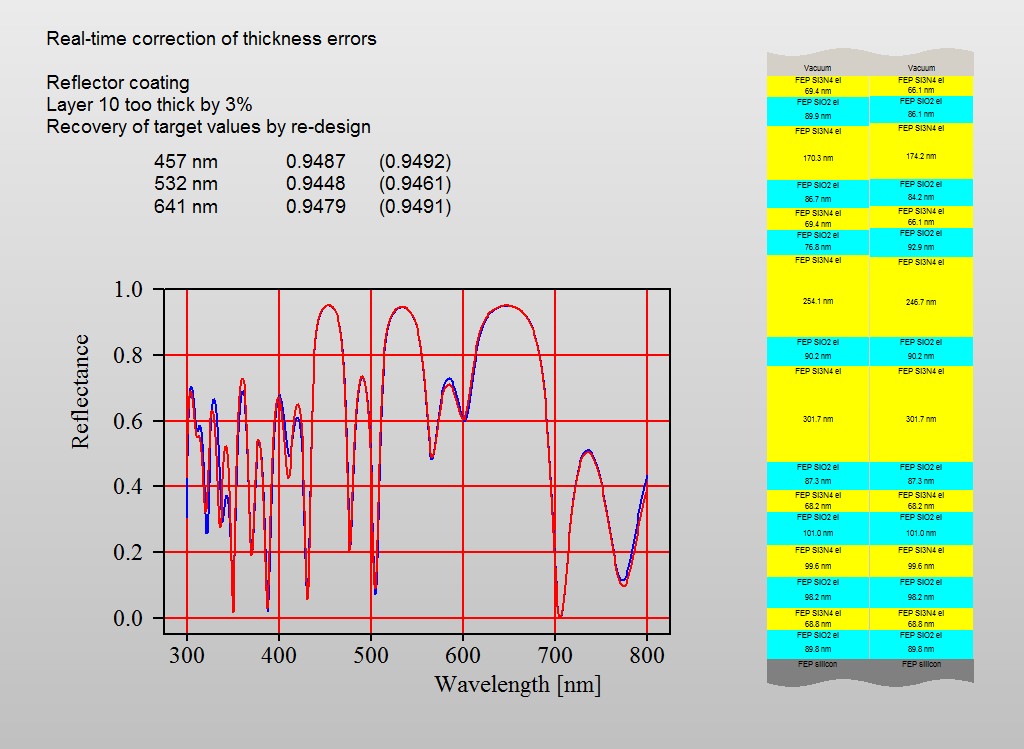

or dynamic, re-computing coating properties in real time while you move values by graphical sliders:

Here is the documentation of the new presentation feature. The online help system provides a link to a demo presentation that you can use to try it out yourself. You must have object generation 3.98 or higher.